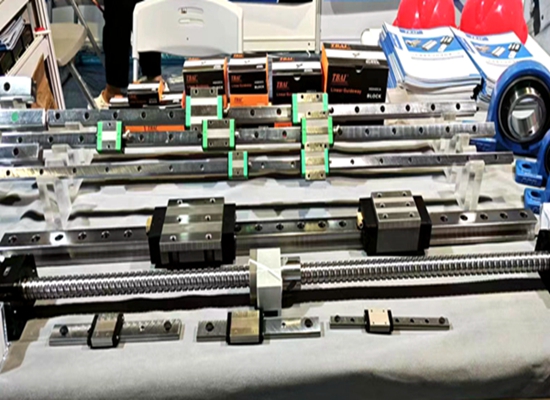

Ball Screw SFU2510-4

Low Noise

High Load

Long Service

High Precision

Walk Smoothly

C7,C10,C5 grade

TBI Technology & Size

Product Introduction

SFU2510-4 belongs to the SFU series ball screw, designed according to industry standard dimensions and reflux structure, compatible with mainstream brands such as TBI's screw nuts. The lead is 10mm, suitable for situations that require a large travel speed.

2. The structure and materials of the screw and nut raceway are heat-treated and precision machined, ensuring smooth ball circulation and low friction resistance. Ball bearings are usually made of chromium steel or stainless steel, while screw shafts can be made of high-precision steel and processed through grinding or rolling processes.

3. Accuracy and lifespan support different accuracy levels (C3/C5/C7), and customers can choose higher accuracy versions based on equipment requirements to improve repeat positioning accuracy and lateral jitter. Under normal use and maintenance, the lifespan is related to the usage environment, lubrication, and load. It is recommended to regularly add lubricating grease according to the user manual and avoid lateral impact loads.

4. Customization and processing capabilities

Length customization: can be cut and end face processed according to requirements.

End processing: supports machining of BK/BF bearing end faces, turning forming, keyways, internal and external threads, etc.

Surface/Material: Accepting stainless steel, coating or special material requirements (corrosion resistance/high temperature).

Anti backlash/pre tightening treatment: Pre tightening nuts or anti backlash structures can be provided to meet the requirements of positioning stability.

Quality Control and Testing

Full process quality inspection: raw material inspection → heat treatment hardness testing → raceway shape and position tolerance testing → dynamic operation testing → lubrication and packaging inspection

Provide inspection reports (size report, hardness report, dynamic balance/torque test sheet)

We can conduct third-party inspection or on-site inspection according to customer requirements

Packaging and Shipping

Standard packaging: rust proof oil wrapping → plastic dust cover → wooden box/cardboard box outer packaging

Long length items are reinforced according to industry requirements and offer multiple shipping methods including sea freight, air freight, and express delivery

Frequently Asked Questions (FAQ)

Q: What is the shortest delivery time for SFU2510-4?

Answer: Regular stock models are usually shipped within 3-7 working days, while customized products depend on the processing volume (it is recommended to communicate in advance).

Q: How can I confirm whether I need C3 or C5 precision?

Answer: If the device requires high precision for repeated positioning (such as precision machining/testing equipment), it is recommended to choose a higher precision level; For general automated handling or speed priority situations, C5/C7 is sufficient.

Q: Can the end shaft or special fitting be processed according to the diagram?

Answer: Sure. Both drawings and samples are acceptable, and the engineering department will issue a technical confirmation letter and mark the machining tolerances.

Ordering Information (Example)

Ordering methods: online ordering/email inquiry/phone confirmation

Minimum Order Quantity (MOQ): 1 piece (depending on configuration and length)

Payment method: T/T, Alipay/WeChat (domestic buyers), etc

Contact information: Please provide in the inquiry: model, required total length, end face processing requirements, accuracy level and purpose/working environment

Conclusion (for customer service/business opportunity follow-up)

We provide one-stop services from standard parts to high-precision customization, with a mature processing and quality inspection system that supports small batch trial orders and large batch supply. If you need samples or engineering technical support, please contact us directly.