Industry News

Among the numerous technical parameters of bearings, there is a often overlooked but far-reaching "invisible role" - clearance. Although it is not conspicuous, it directly determines whether the equipment can operate smoothly and for a long time. Choosing too big, the machine shakes like a sieve;

2026/01/31 12:45

The single ball spline scheme allows the nut and screw to be replaced separately, which not only has high precision and reliability, but also provides greater flexibility in maintenance and material preparation. For systems that require long-term stable operation, it is a highly cost-effective

2026/01/24 14:29

Proper installation and disassembly are key to ensuring the performance and lifespan of bearings. Improper operation can easily lead to damage to the raceway, deformation of the cage, and even early failure.Installation points:Clean environment: Ensure that the shaft, bearing seat, and tools are

2026/01/17 17:14

In the design of rolling bearings, although the cage does not directly bear the load, it plays a key role in the stability, service life, and applicable working conditions of operation. The selection of materials should comprehensively consider factors such as rotational speed, temperature,

2025/12/27 14:12

Cast iron and cast steel are two commonly used materials for bearing seats, each with its own advantages and disadvantages, suitable for different occasions. Cast iron bearing seats are suitable for low-speed, light load, and situations that do not require high-precision operation due to their low

2025/12/13 09:22

In mechanical design, although joint bearings are small in size, they bear the key tasks of complex loads and frequent swinging. Faced with a dazzling array of models such as GE, GAC, GX, etc., many engineers often feel confused: what exactly do these letters represent? In fact, each code

2025/12/03 13:07

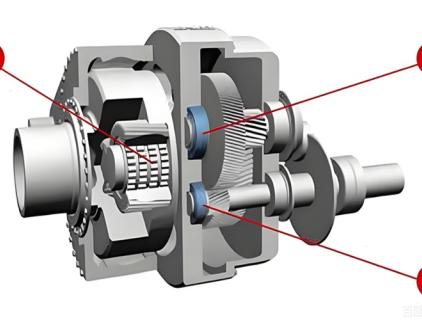

In the design of mechanical systems, the size of the shaft is usually determined first. The shaft diameter, shaft length, and the working load it bears will directly affect the overall layout of the equipment. After determining the specifications of the shaft, engineers need to choose suitable

2025/11/24 16:52

The reliability of liquid dynamic pressure bearings in high-speed rotating machinery is directly related to the overall lifespan and operational safety of the machine. Its core lies in maintaining a stable lubricating oil film - once the oil film ruptures, direct contact with the metal surface will

2025/11/17 11:02

In mechanical design, the "ultimate speed" of bearings is a often overlooked but crucial parameter. It refers to the maximum rotational speed at which a bearing can operate safely and stably under specific lubrication and installation conditions. Once the actual working speed exceeds this threshold

2025/11/11 14:55

In the automotive cooling system, the water pump is a key component that ensures the normal operation of the engine, and its internal "core joint" - the shaft bearing, is quietly changing the traditional design logic. It is not a simple upgrade of ordinary bearings, but an innovative structure that

2025/10/20 15:48

In the drive systems of high-speed rotating motors, precision running machine tools, and even new energy vehicles, a name repeatedly appears: GCr15. Why can this seemingly ordinary steel become the "standard configuration" for global bearing manufacturing? The material logic behind it is far more

2025/09/18 11:48

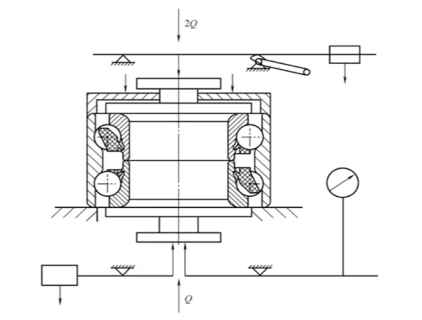

The smaller the clearance, the better. Matching the working conditions is the keyThe internal clearance of rolling bearings directly affects the stability, temperature rise, and service life of equipment operation. Seemingly small 0.01mm gap changes may cause systematic failure at high temperatures

2025/09/10 09:13